|

Product Details:

|

| Product Name: | Carbon Steel Elbow | Usage: | Oil Gas Water Industrial |

|---|---|---|---|

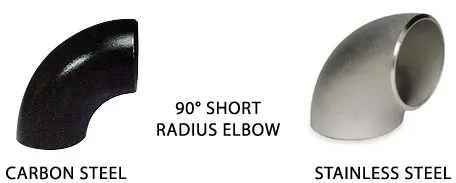

| Customized Support: | OEM | Material: | Carbon Steel |

| Package: | Wooden Box/Pallet | Type: | Seamless/Seam Remove |

| Nature Of Company: | Factory | Connection: | Welding, Welded Connection |

| Color: | Black Oil Galvanized | Transportation: | By Sea |

| Highlight: | api 5l carbon steel pipe elbow,22.5 degree carbon steel pipe elbow,painted 22.5 degree elbow carbon steel |

||

Company Profile

I-Flow has been specializing in flow control area for more than 15 years.

As a professional supply chain manager of flow control products, I-Flow offer gate,globe,check,butterfly,ball, JIS and DIN marine valves,strainers,actuators, flanges, pipes and fittings,with pressure range from 0.5-6.4MPA, size from DN15-DN3000, as well as valve design, inspection, consultation services etc.

With profound understanding of the importance of customer requirement and 15 years experience,we offer highly cost-effective products,enjoying a good reputation. And we have various kinds of certificates, such as ISO9001, API, ABS,PED, UL,FM, WRAS, DVGW, DNV, LR, BV etc, selling to more than 30 countries. Being a reliable partner, we are looking forward to cooperating with you.

Carbon Steel Pipe Elbow Api 5l Black Painted Carbon Steel Pipe Elbow 22.5 Degree

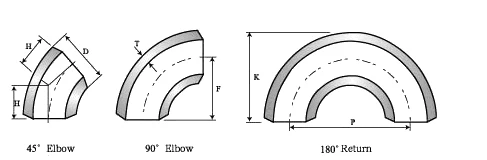

1. Elbow(45deg, 90deg and 180deg lr and sr)

2. Size: 1/2"-36" can be seamless, 5"-110" can be welded"

3. Thickness: Sch20, Std, xs, xxs, sch10, sch20, sch30, sch40, sch60, sch80, sch160, etc.

4. Carbon steel: A234 wpb, st37.2, st35.8, API 5L GR B, API 5L X42, API 5L X52, API 5L X60, API 5L X65, API 5L X70 and so on.

5. Usage: Petroleum industry, Refinery Company, fertilizer industry, power station, shipbuilding, onshore platform

Advantages And Characteristics

| Product Description | |||

| Type | Carbon steel Butt-welding pipe Fitting(Elbow, Tee, Reducer, Cross, Cap , Stub Ends) | ||

| Carbon steel Forged Pipe Fitting(Elbow, Tee, Cross ,Union, Coupling, Outlet, Boss, Bushing, Plug, Nipple) | |||

| Size | Seamless | DN15-DN800(1/2"-32") | |

| Welded | DN450-DN2500(18"-100") | ||

| forged | DN8-DN100(1/4"-4") | ||

| Wall Thickness | Sch20-Sch160 XXS | ||

| Material | America | A234WPB/C, A420WPL6, A420WPL3, MSS SP75 WPHY42/46/52/56/60/65/70 | |

| Europe | P250GH, St45.8, St37.0, St35.8 | ||

| Standard | ASME, MSS, EN, DIN, ISO, JIS, GB, SH, HG, JB, GD | ||

| Certificate | ASME, ABS, BV, GL, TUV, CCS, TS, ISO | ||

| Features | Our products are corrosion and high-temperature resistant | ||

| We can also produce other specifications according to customers' requirements | |||

| Best price / Prompt Delivery / High Quality | |||

| Packing | Plywood case, fumigated wooden case, pallet or as per customers' requests | ||

| Product Name | Carbon Steel Pipe Elbow Api 5l Black Painted Carbon Steel Pipe Elbow 22.5 Degree |

| Standard | ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| Materials |

Stainless steel:ASTM/ASMES/A182F304 | F304L |F304H | F316 | F316L | F321 | F321H | F347|316Ti | 309S |310S | 405 |409|410 | 410S | 416 | 420 | 430 | 630 | 660 | 254SMO | 253MA | 353MA Nickel Alloy: ASTM/ASME S/B366 UNS N08020| N04400|N06600| N06625| N08800| N08810|N08825| N10276|N10665|N10675|Incoloy 800 | Incoloy 800H | Incoloy 800HT | Incoloy 825 | Incoloy 901 | Incoloy 925 | Incoloy 926, Inconel 600 | Inconel 601 | Inconel 625 | Inconel 706 | Inconel 718 | Inconel X-750, Monel 400 | Monel 401 | Monel R 405 | Monel K 500 Hastelloy:HastelloyB | HastelloyB-2 | HastelloyB-3 | HastelloyC-4 | Hastelloy C-22 | Hastelloy C-276 | Hastelloy X |Hastelloy G | Hastelloy G3 Ti alloy:ASTM R50250/GR.1 | R50400/GR.2 | R50550/GR.3 | R50700/GR.4 | GR.6 |R52400/GR.7 | R53400/GR.12 | R56320/GR.9 |R56400/GR.5 Carbon steel: A234 WPB | A420 WPL6 |

| Marking | Supply Logo + Standard + Size(mm) + HEAT NO +or as your requirement |

| Test | Chemical Component Analysis, Mechanical Properties, Metallurgical Analysis, Impact Testing, Hardness testing , Ferrite Testing, Intergranular corrosion testing, X-ray Inspection (RT), PMI, PT, UT, HIC & SSC test, etc. or as your requirment |

| Certificates | ISO, BV, CE, PED, KOC, CCRC, PDO, CH2M HILL and etc. |

| Applications |

Ø EN 1.4835 has a good weldability and can be welded using the following methods: 1. Shielded metal arc welding (SMAW)

2. Gas tungsten arc welding, GTAW (TIG)

3. Plasma arc welding (PAW)

4. Gas metal arc GMAW (MIG)

5. Submerged-arc welding (SAW) Ø Typical application areas for 1.4835: 1. Ovens 2. Construction 3. Building 4. As details at high temperature |

| Advantages |

ü Welding ü Machining |

The three most common types of elbows in piping are the 45, 90, and 180 degrees (or return elbow), as shown in the image:

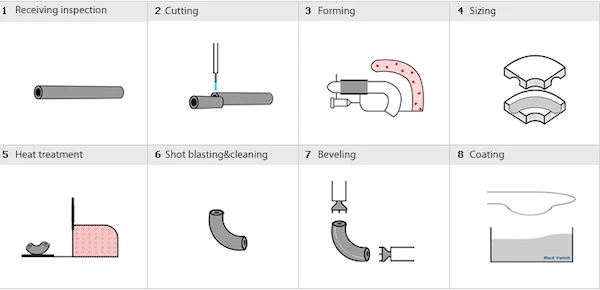

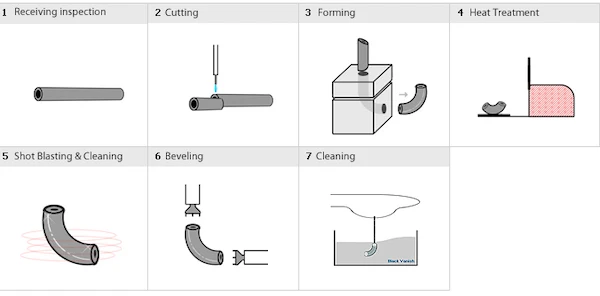

Buttweld elbows below 24 inches in diameter are produced by cutting, heating and bending seamless steel pipes; pipe elbows of larger sizes are manufactured, instead, from welded pipes or steel plates.ASME B16.9 buttweld elbows are manufactured in a wide range of dimensions (combinations of outside diameter and wall thickness) to fit ASME B36.10 and ASME B36.19 carbon, alloy and stainless steel pipes of any size between 2 and 48 inches (and above).

Buttweld elbows 45 and 90 degrees can be manufactured in different ways, the main ones are the “mandrel process” and the “cold forming” (other methods are the elliptical forming and the double-seam welding method).

Mandrel Process

Cold forming

Manufacter supplis strightly , of good quality and big quantity

Used to the pipes connecting ,

Petroleum, chemical, power plant, gas, metallurgy, shipbuilding, construction, etc

![]()

![]()

![]()

Contact Person: Mr. Du

Tel: 18931701057